HASCO and SEEBURGER cooperate to build Industry 4.0 Benchmark Factory “HIT”

HASCO announced to establish digital HIT (HASCO Intelligent Transformation) platform with strategic partner SEEBURGER cooperating in the EDI and B2B field.

HASCO announced to establish digital HIT (HASCO Intelligent Transformation) platform with strategic partner SEEBURGER cooperating in the EDI and B2B field.

HASCO, the leading automotive components company in China and member of SAIC Group, held a signing ceremony of strategic cooperation on May 5, 2017 in Shanghai. HASCO, inheriting from SAIC automotive components business, independently focuses on R&D, production and marketing of automotive components. Aiming to pioneer in industry 4.0, HASCO announced to establish HIT (HASCO Intelligent Transformation). The company held a launch ceremony of strategic cooperation with SEEBURGER, SAP, SIEMENS, Huawei and GE, which are committed to promoting intelligent manufacturing works in the future, exploring front-tier practices of enterprise transformation, building an informational, digital and automatic integration platform so as to enhance efficiency, reduce costs and spark innovation throughout the automotive industry.

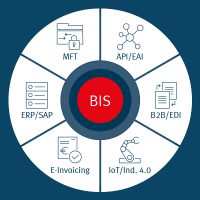

SEEBURGER, as a global leading B2B/EDI solution and software provider, has been focused on automotive industry for over 30 years. The company offers seamless internal and external business integration solutions, acts as the integration engine to drive digital transformation and leads the way to industry 4.0 for automotive manufacturers. SEEBURGER will apply their best practice for HASCO HIT by offering professional consulting, design and implementation services to realize comprehensive and seamless business integration as part of HIT.

The representative of HASCO emphasized that HASCO will work together with these reputable partners to build the digital HIT platform and expressed that HASCO will have further and deep cooperation with SEEBURGER in the EDI and B2B field. HASCO further explained that they will take a unified infrastructure to support HIT’s operation, and that they plan to spread the HIT platform to 50 factories within 3 years. In 2025, the HIT platform aims to cover 200 systems, connect 500,000 sensors and the annual throughput capability will reach 200TB.

Guided by the strategic initiatives of “Internet Plus” and “China Manufacturing 2025”, SEEBURGER and HASCO will work together and make use of each other’s advantages to jointly work on establishing HIT, a platform for realizing the digital management and innovation practice of enterprise transformation.

Thank you for your message

We appreciate your interest in SEEBURGER

Get in contact with us:

Please enter details about your project in the message section so we can direct your inquiry to the right consultant.

Written by: Gang Huang

Gang Huang, Managing Director of the SEEBURGER office in China, has been with SEEBURGER since 2010. He is responsible for the management, business development, market promotion, marketing and customer support related to SEEBURGER's business integration technology for various industries in China, such as automotive, logistics, CPG/retail, high-tech and healthcare. Gang Huang has nearly 20 years of integration experience in optimizing complex business processes and providing solutions for enterprise application integration, EDI, B2B, MFT, API, digital transformation and industry-specific technology initiatives with on-premises systems as well as in the cloud. Gang Huang holds a Bachelor's degree in Industrial Engineering and Management from Hohai University of China and a Master's degree in Computer Science from TU Berlin.